We were consulted by a customer who had trouble when they imported cargo for the first time to handle in a tank container from China and had it delivered.

When they tried to start work, they found that a hose and joint were required to connect the destination tank to the tank container. They cancelled the work and decided to adjust the schedule to a later date.

The customer consulted us, saying that they did not know the specifications of the destination tank and the tank container and did not know what they should prepare. We checked the destination tank and the tank container and investigated what was required. We also received a request for manufacture of the hose and joint.

We solved technical problems when importing using tank containers for the first time.

| Industry | Transportation |

|---|---|

| Type of cargo | Chemicals |

| Purpose | Tank container specifications |

| Transportation area | Domestic (Japan) |

A customer imported cargo in a tank container from China which was handled for their first time. However, there was a technical problem with the connection between the tank container and the destination tank. After being consulted by the customer, we used expert knowledge and technology to solve the issue.

- The customer confirmed that a hose and joint were required to connect the destination tank to the tank container.

- The specifications of the destination tank and the tank container were unclear, so they did not know what to prepare.

- We checked the specifications of the destination tank and the tank container.

- A hose and joint were manufactured.

- By storing the tank container at our storage location, we were able to work without time limits.

- The hose and joint were both compatible with the tanks, and we completed delivery without incident.

Trouble occurred upon delivery after importing using a tank container for the first time.

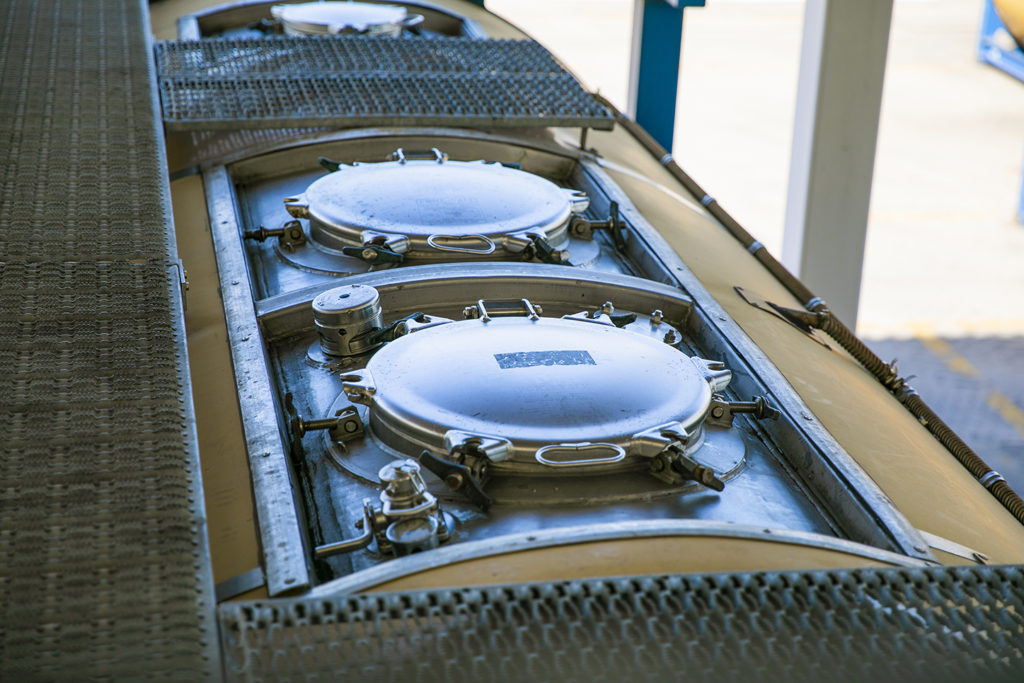

We checked the specifications of the tank container, etc., one by one.

The tank container was stored at our storage location. After that, we checked the specifications of the destination tank and the tank container.

First of all, we proposed to compare the actual tank container with its drawings. When doing so, we also explained there were cases of differences between drawings and actual tank containers.

For the destination tank specifications, we asked the customer for the entrance procedures and conducted a survey there later. For the manufacture of hoses and joints, we proposed manufacture using genuine tank container parts.

The required parts were manufactured and we were able to complete delivery.

As we were able to confirm the actual tank container and check it against the drawings, we were able to prevent specification errors. Also, we were able to confirm the destination tank.

Based on those results, we also manufactured a hose matched to the joint using genuine tank container parts. As the tank was stored in our storage location, there was no limit on the storage period and the manufacturing period was not affected.

We sent the completed fixtures directly to the destination to simplify the process. The hose and joint were both compatible with the tanks, and we were able to complete delivery without incident.

and other matters, click here